posted: 2010-03-15

Columbia University and a research company have entered into a collaboration and licensing agreement for technology that extracts carbon dioxide from the atmosphere, it was announced today. The company, Global Research Technologies, hopes to have units within two years that would capture up to a ton of CO2 a day.

Today, only living plants, atmospheric chemical cycles and other natural systems can pull large volumes of CO2 out of the air. Efforts to snare manmade CO2, released primarily from the combustion of fossil fuels, are not yet viable at a large scale, but some scientists think they hold great promise in tackling climate change. Most financial support so far has gone to projects that capture CO2 at large point-sources such as coal plants--not from the atmosphere at large--and policy makers have focused mainly on reducing emissions by promoting energy efficiency and renewable energy sources.

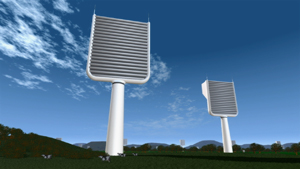

The technology to be commercialized by GRT has been called a “synthetic tree.” It uses proprietary resins and processes to absorb CO2 from the air, potentially at a rate a thousand times faster than natural trees. The company says that the trees, with a predicted lifespan of 15 years, consume minimal energy during the carbon capture process, and share with other carbon-capture technologies similar energy requirements for storing the resulting carbon. GRT’s founders are Klaus Lackner, director of the Earth Institute’s Lenfest Center for Sustainable Energy, and Allen Wright, a senior staff associate also at the Earth Institute.

“With this technology, we can enter today’s CO2 markets and build for tomorrow’s demand for climate management technologies,” says GRT’s CEO, William Gridley. Gridley sees air capture as economically competitive and complementary to other forms of carbon capture now being developed. He estimates that initial units will be able to capture up one ton of CO2 per day at a cost of less than $100 per ton. GRT plans to sell diluted captured gas as a nutrient for greenhouses and algae farms, and to eventually sell compressed gas for drink carbonation, to make dry ice, and for other niche markets that today total $1 billion to $2 billion per year.

In the long run, Lackner predicts carbon regulation could transform carbon capture into a multibillion dollar market. “By driving cost down to $50 a ton or less, carbon capture can become a cost-effective option for companies looking to meet regulations emerging in Europe, North America and elsewhere,” said Lackner. He hopes the trees can be manufactured in dormant auto plants, restoring lost jobs and breathing new life into local economies, for both national and global economic and environmental benefit.

“One of the unique advantages of this technology is that it makes possible the capture of CO2 from the air anywhere in the world. Unlike the few existing carbon capture approaches, it’s not necessary to co-locate these units with sources of CO2 emissions,” said James Aloise, who manages a portfolio of intellectual property relating to green technology for Columbia Technology Ventures, the university’s technology transfer office, which announced the agreement. “This inherent flexibility and mobility improves access to the technology, which has true potential to make a global impact.”

Saturday, April 17, 2010

Columbia University joins ‘Synthetic Tree’ venture -- devices would pull carbon from air

Subscribe to:

Post Comments (Atom)

1 comment:

I too think it is very possible we will need to capture CO2 from air and that this route may well be more attractive than battery operated vehicles see

http://jemsavestheplanet.blogspot.com/2010/03/vehicle-carbon-capture.html

While regenerating a pressure swing absorption resin is likely to be much less energy intensive than thermal regeneration of competitive chemical systems I am guessing capital requirements for the compressor for vacuum regeneration are very substantial. I would also imagine it is easier to collect and replace a liquid such as sodium or potassium carbonate solution in the trees than a solid adsorbent. But if the all in cost including capital charges is really less than $100/ton this is clearly the way to go.

Post a Comment